Product

Home> Product >Vacuums>Neocera

Home> Product >Vacuums>Neocera

Neocera

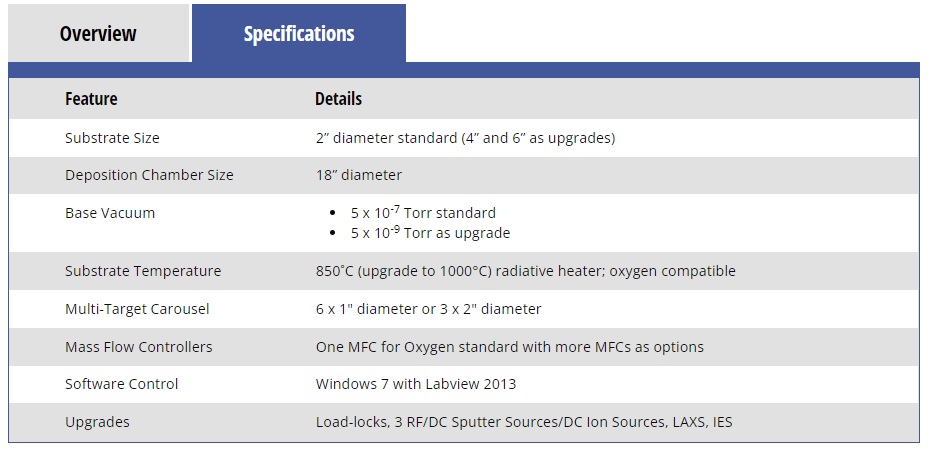

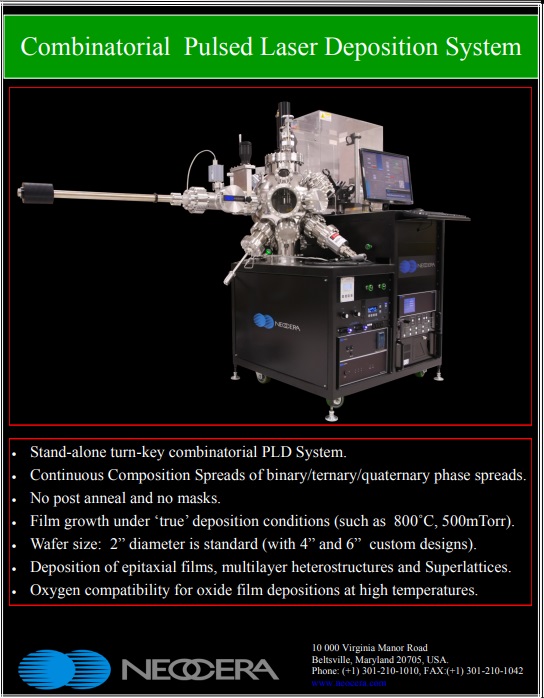

Combinatorial Pulsed Laser Deposition System

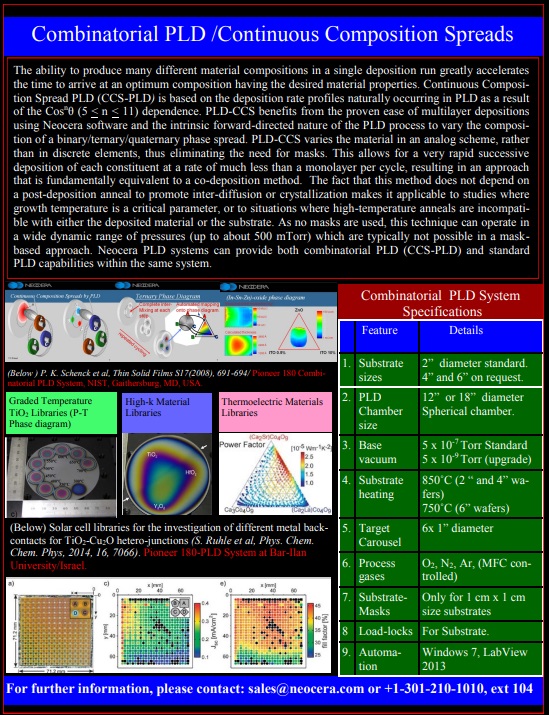

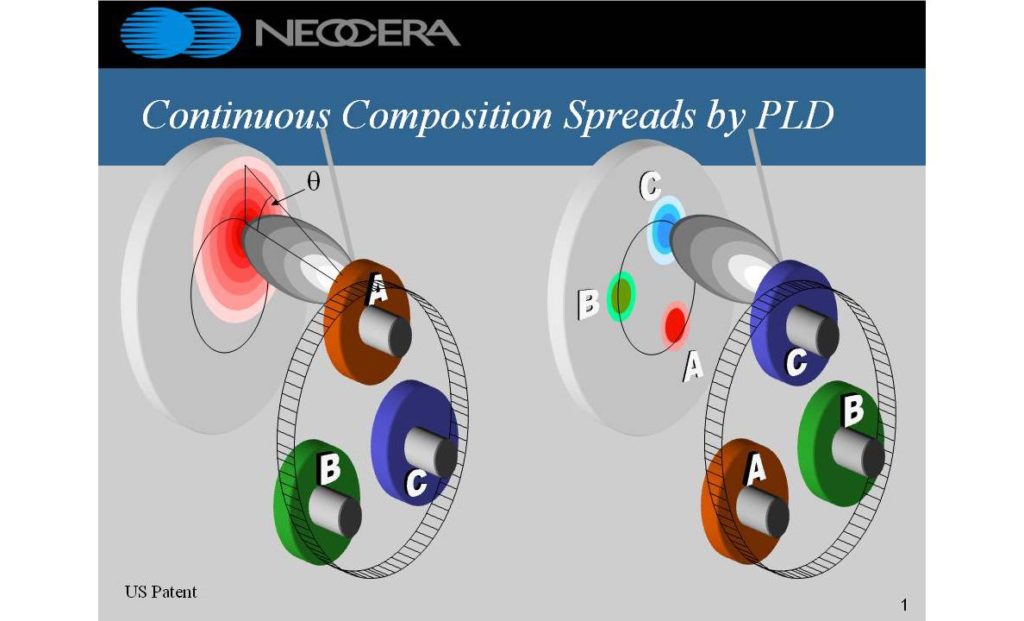

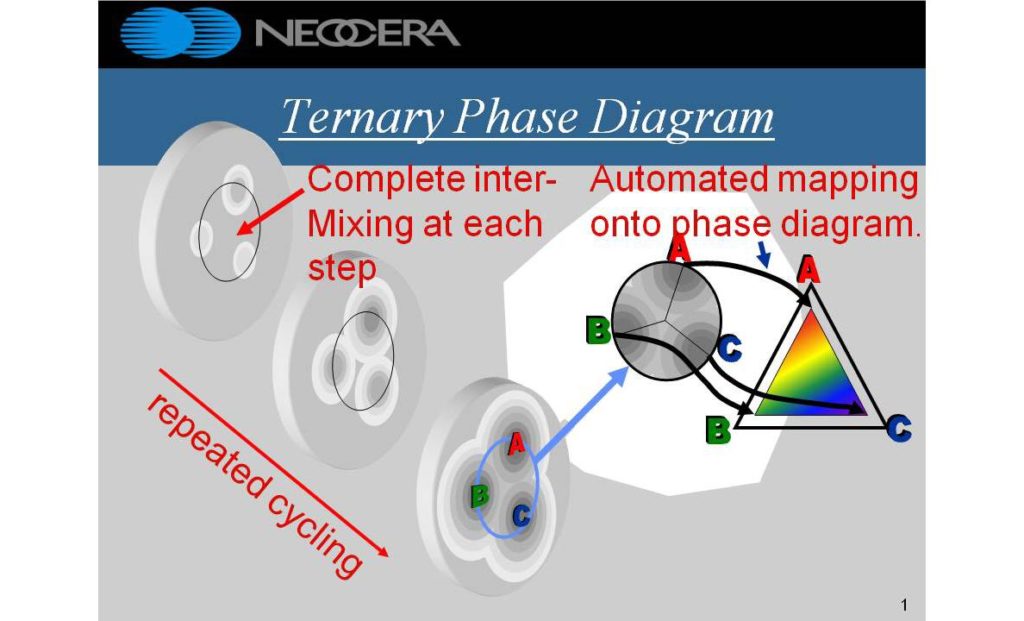

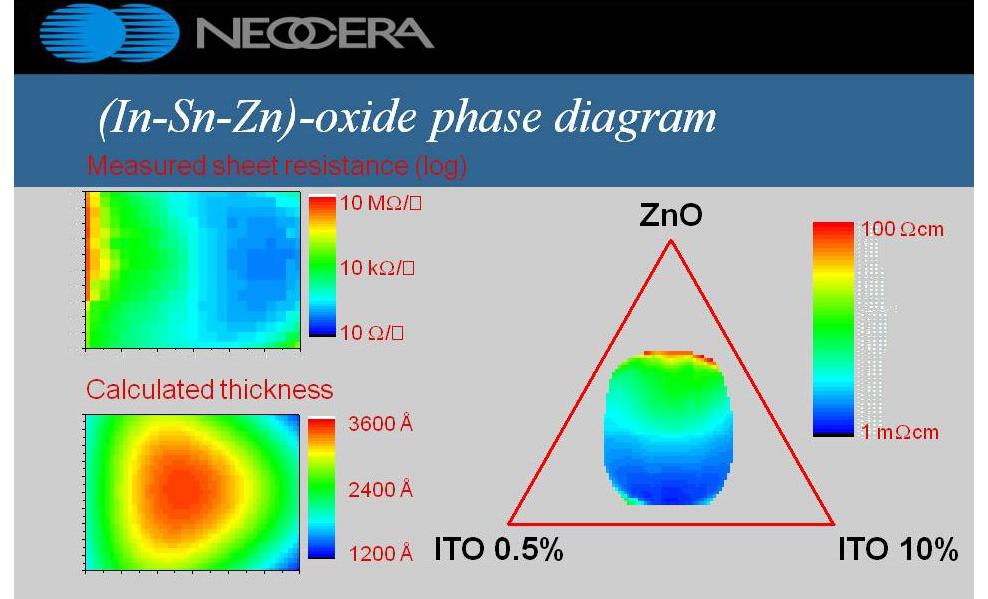

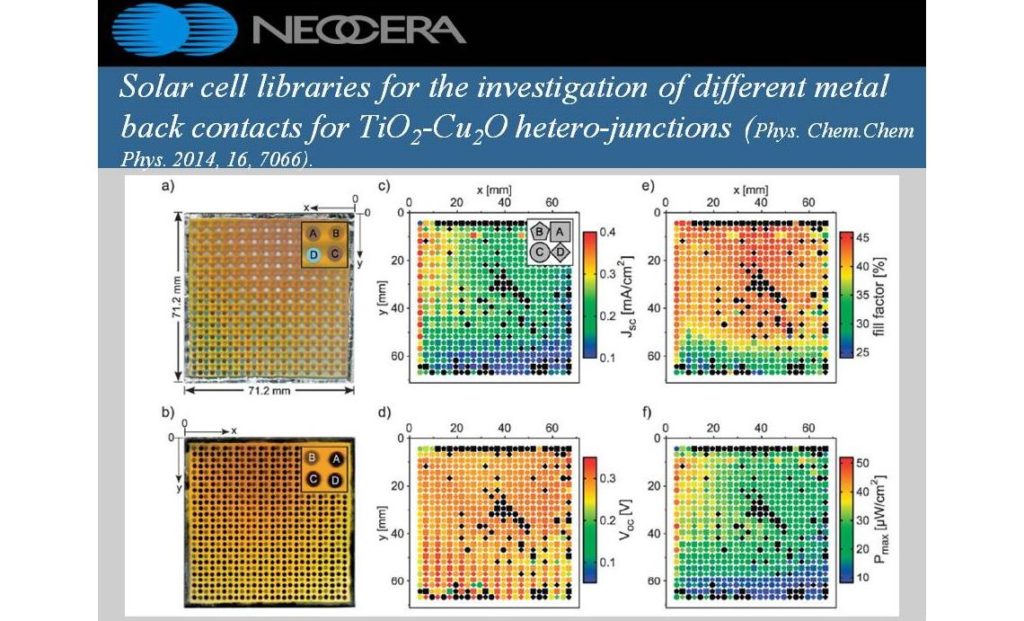

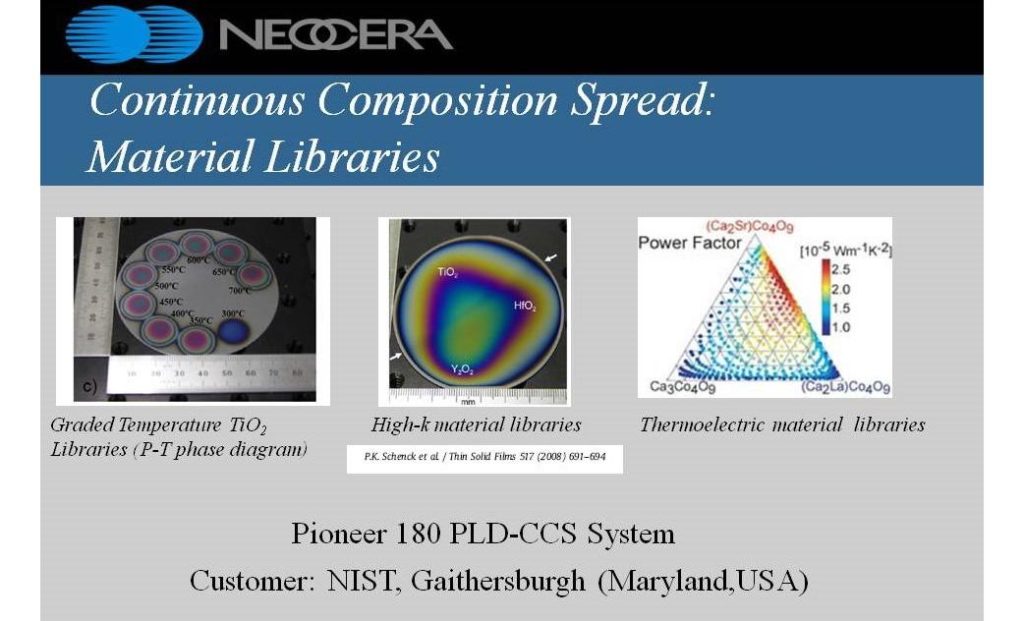

The ability to produce many different material compositions in a single deposition run greatly accelerates the time to arrive at an optimum composition having the desired material properties. Continuous Composition Spread PLD (CCS-PLD) is based on the deposition rate profiles naturally occurring in PLD as a result of the Cosn (θ) (5 ≤ n ≤ 11) dependence. PLD-CCS benefits from the proven ease of multi-layer depositions using Neocera software and the intrinsic forward-directed nature of the PLD process to vary the composition of a binary/ternary/quaternary phase spread. PLD-CCS varies the material in an analog scheme, rather than in discrete elements, thus eliminating the need for masks. This allows for a very rapid successive deposition of each constituent at a rate of much less than a mono-layer per cycle, resulting in an approach that is fundamentally equivalent to a co-deposition method. The fact that this method does not depend on a post-deposition anneal to promote inter-diffusion or crystallization makes it applicable to studies where growth temperature is a critical parameter, or to situations where high-temperature anneals are incompatible with either the deposited material or the substrate. As no masks are used, this technique can operate in a wide dynamic range of pressures (up to about 500 mTorr) which are typically not possible in a mask-based approach. Neocera PLD systems can provide both combinatorial PLD (CCS-PLD) and standard PLD capabilities within the same system.