Product

Home> Product >Vacuums>Neocera

Home> Product >Vacuums>Neocera

Neocera

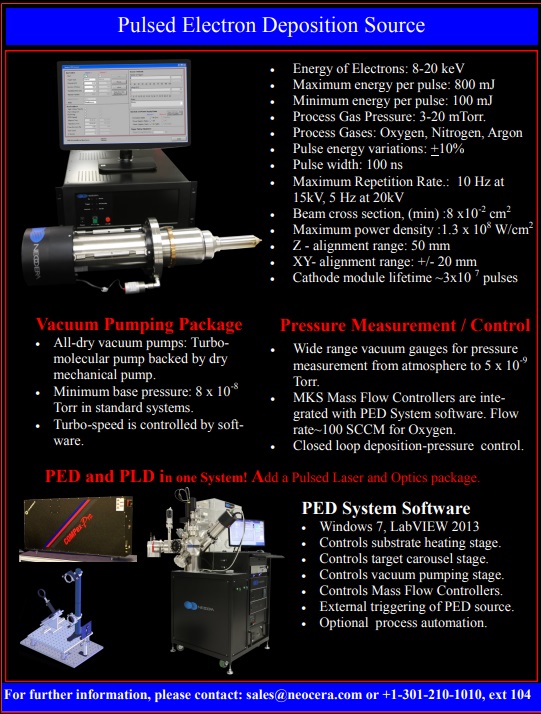

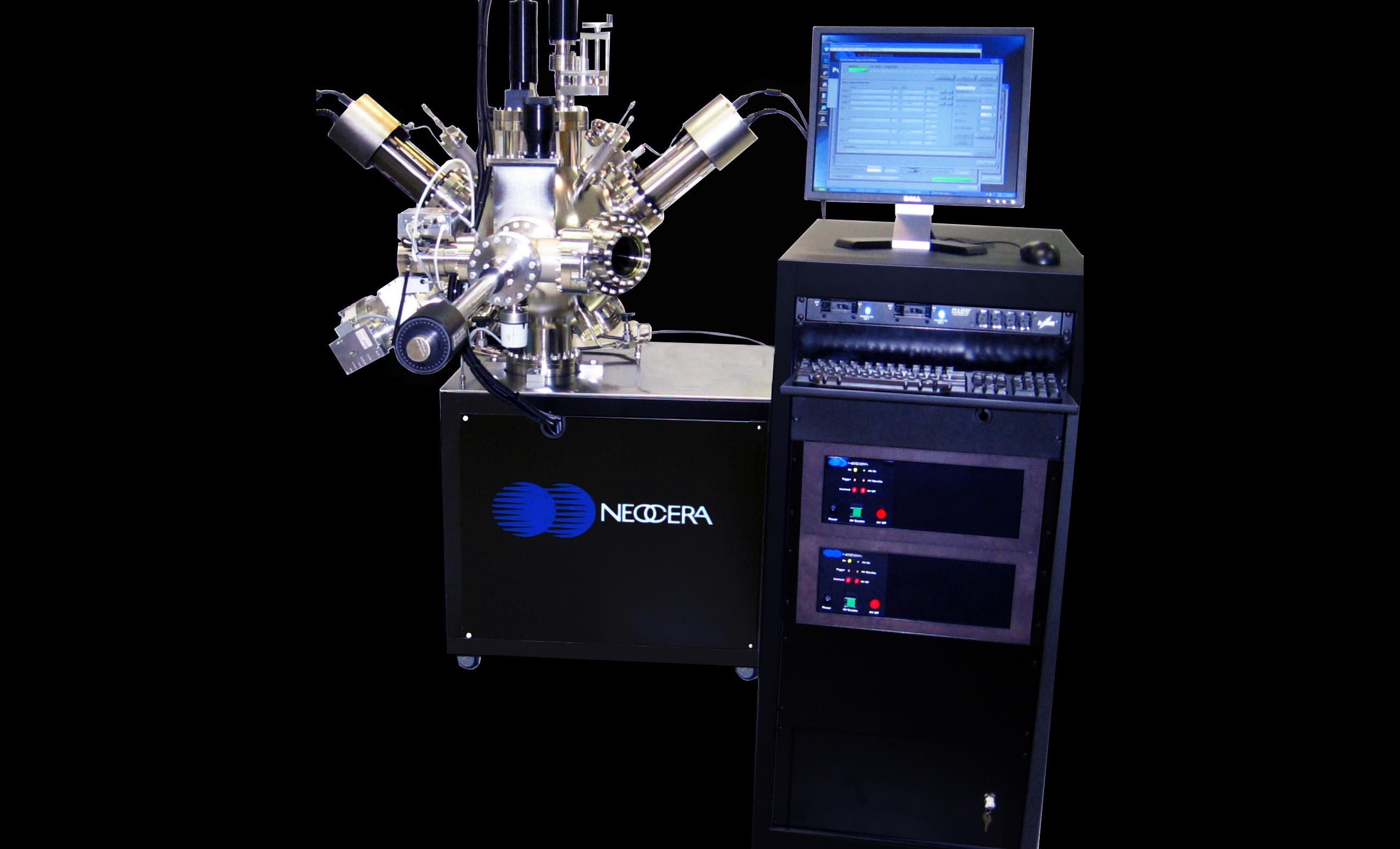

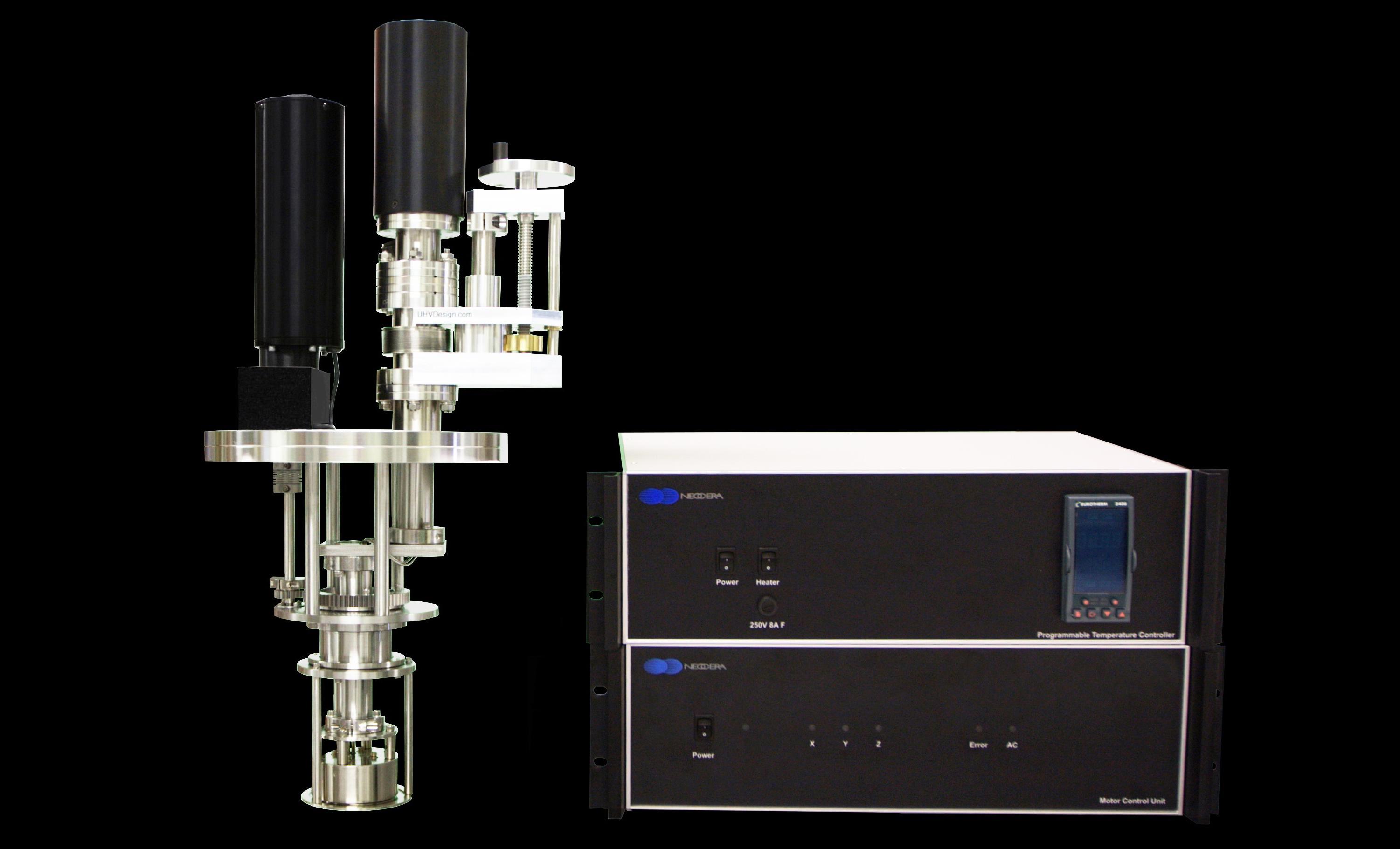

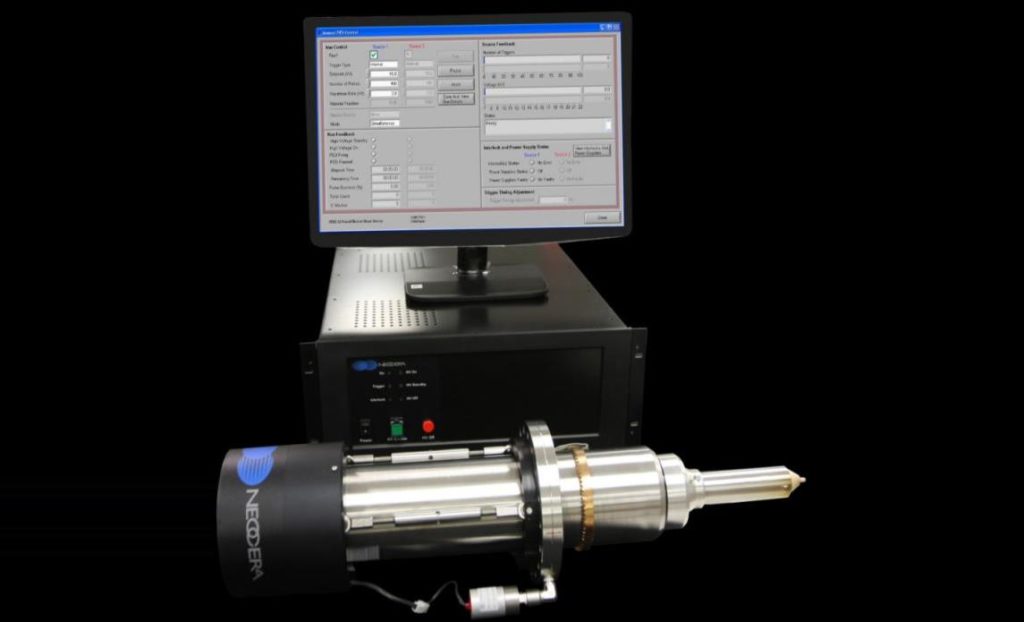

Pioneer 180 PED System

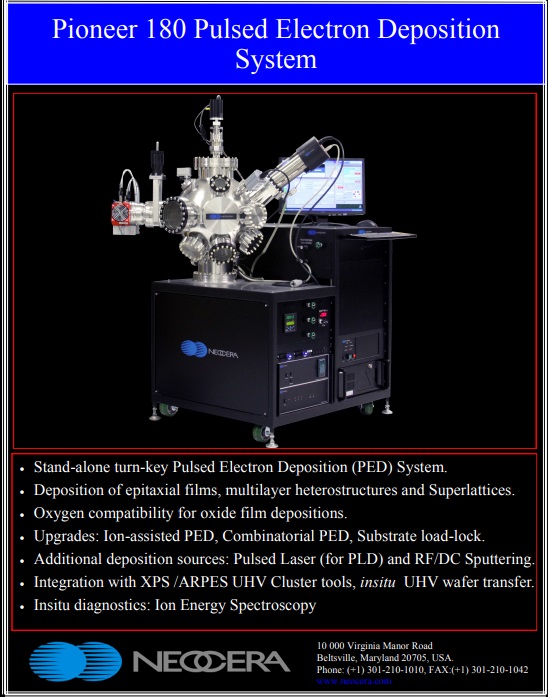

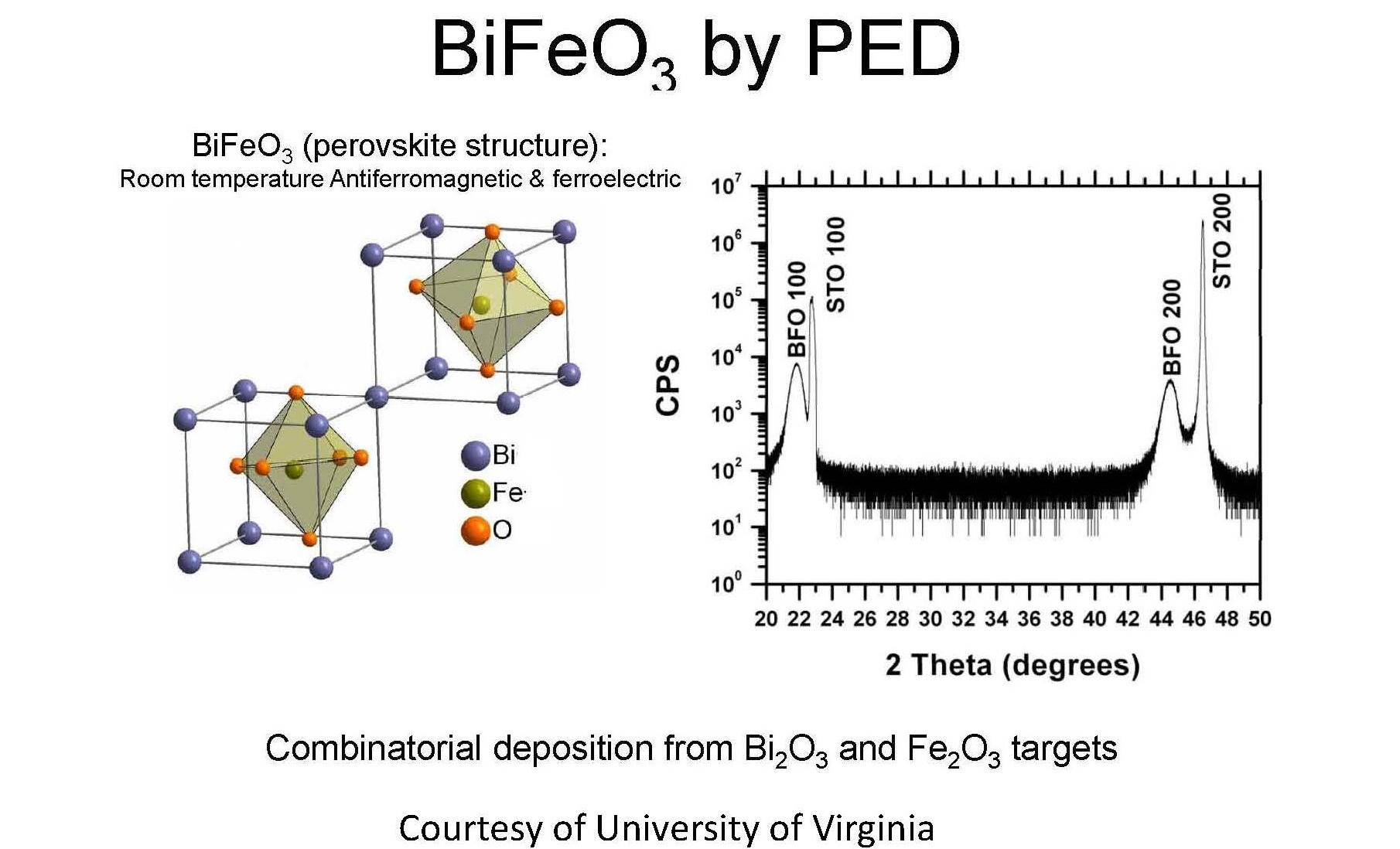

In Pulsed Electron Deposition (PED), a pulsed (80-100 ns) high power electron beam (approximately 1000 A, 15 keV) penetrates approximately 1 μm into the target resulting in a rapid evapora-tion of target material. The non-equilibrium heating of the target facilitates stoichiometric ablation of the tar-get material. Under optimum conditions, the target stoichiometry is preserved in the deposited films. All ma-terials, can be deposited as thin films with PED.

In contrast to CW techniques such as conventional e-beam evaporation, the main feature of the pulsed sys-tems is the ability to generate a high power density of ~108W/cm2 at the target surface. As a result, thermo-dynamic properties of the target material become unimportant for the evaporation process. This is particularly advantageous in the case of complex, multi-component materials. As in the case of Pulsed Laser Deposition (PLD), the Pulsed Electron Deposition (PED) technique provides a unique platform for depositing thin films of complex materials on a variety of technologically important substrates, with a unique strength of extending the range of materials (those not accessible to PLD) and applications. Unlike PLD, where the ablation process is critically dependent on the optical absorption coefficient of the target material, in PED, the ablation de-pends only on the range of electrons in the target. For most materials this range is of the order of a few mi-crons. SiO2with a large optical band-gap of 10eV for example, is transparent to 248nm Kr-F excimer laser radiation. In PED however, the high-power electrons can strongly couple to the target material (SiO2), lead-ing to SiO2 film deposition. The beam-solid interaction mechanism is quite different in PED relative to PLD. This unique difference provides materials resarchers a mechanism to extend the parameter-space required for certain novel materials fabrication.

In contrast to CW techniques such as conventional e-beam evaporation, the main feature of the pulsed sys-tems is the ability to generate a high power density of ~108W/cm2 at the target surface. As a result, thermo-dynamic properties of the target material become unimportant for the evaporation process. This is particularly advantageous in the case of complex, multi-component materials. As in the case of Pulsed Laser Deposition (PLD), the Pulsed Electron Deposition (PED) technique provides a unique platform for depositing thin films of complex materials on a variety of technologically important substrates, with a unique strength of extending the range of materials (those not accessible to PLD) and applications. Unlike PLD, where the ablation process is critically dependent on the optical absorption coefficient of the target material, in PED, the ablation de-pends only on the range of electrons in the target. For most materials this range is of the order of a few mi-crons. SiO2with a large optical band-gap of 10eV for example, is transparent to 248nm Kr-F excimer laser radiation. In PED however, the high-power electrons can strongly couple to the target material (SiO2), lead-ing to SiO2 film deposition. The beam-solid interaction mechanism is quite different in PED relative to PLD. This unique difference provides materials resarchers a mechanism to extend the parameter-space required for certain novel materials fabrication.