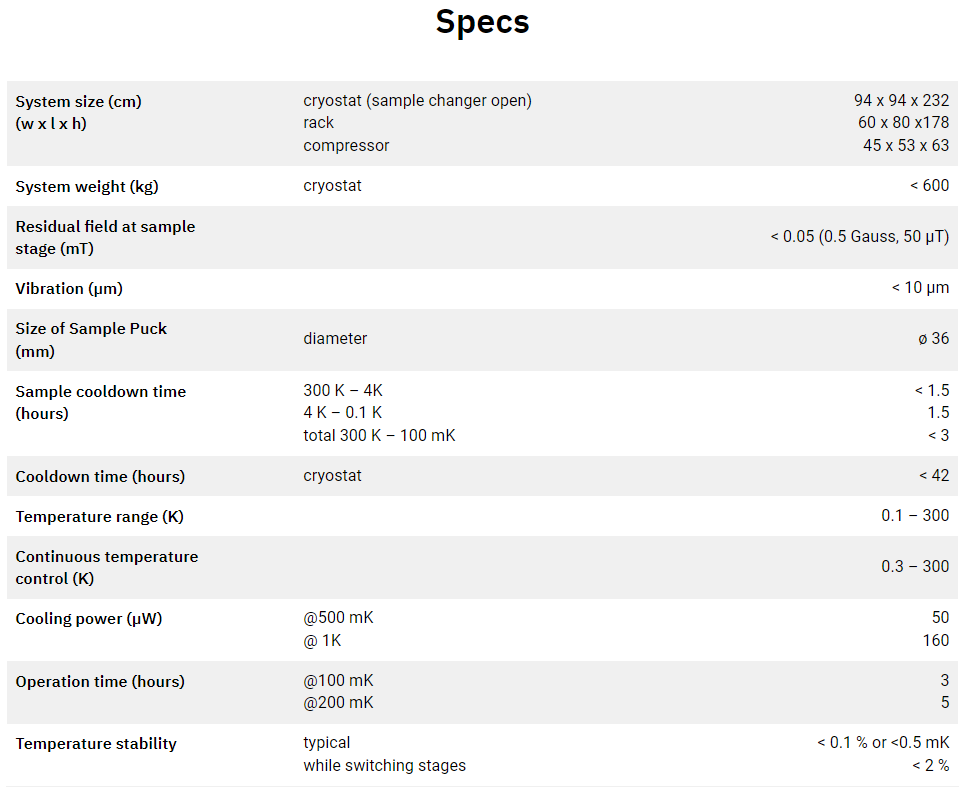

Product

Home> Product >Cryogenics>Kiutra

Home> Product >Cryogenics>Kiutra

Kiutra

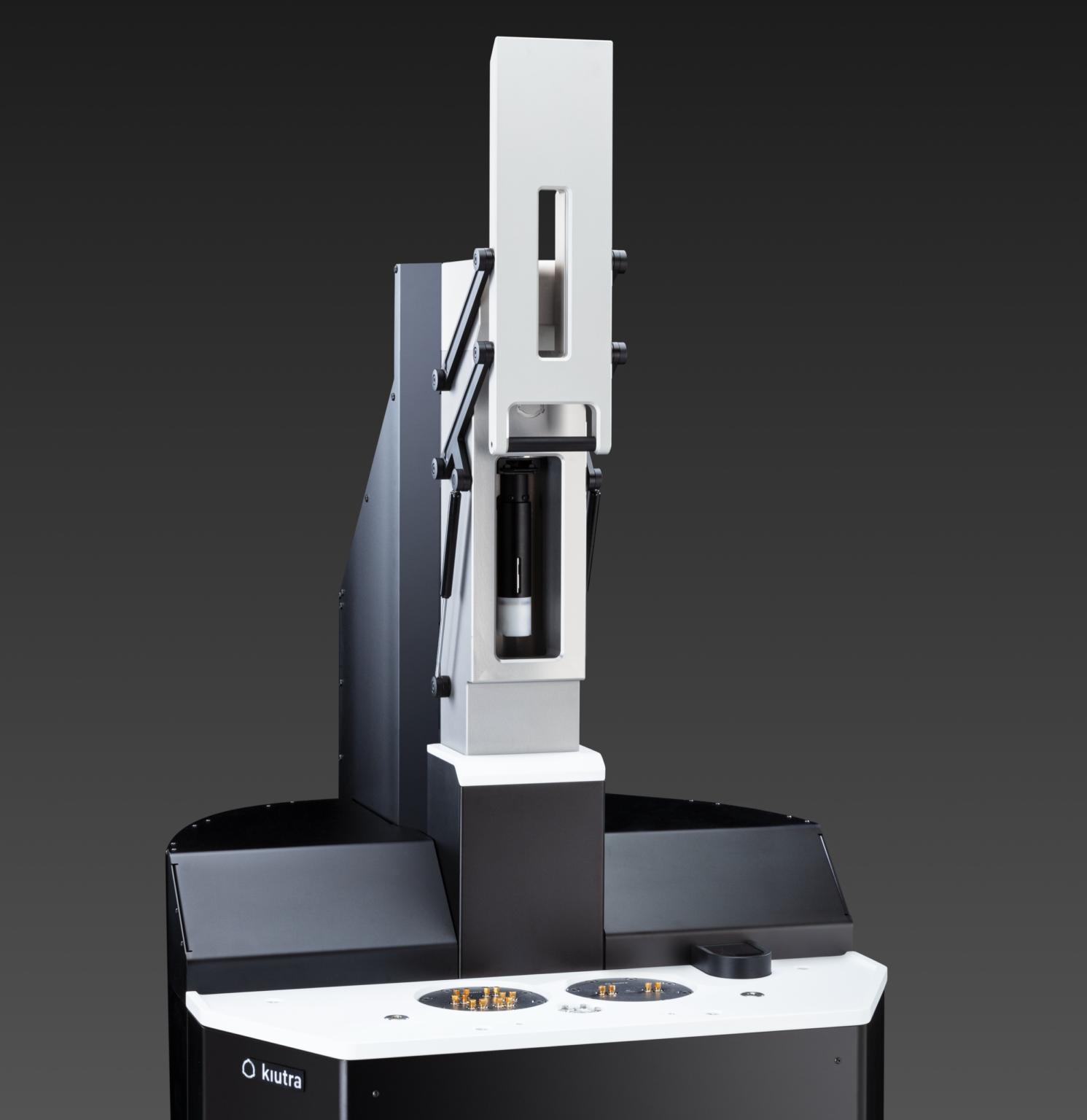

L-Type Rapid

Super-fast Characterization Cryostat for sub-Kelvin and Kelvin Temperatures

DETAILS

| Fast sample characterization With the L-Type Rapid’s sample exchange mechanism you can prepare your sample outside the cryostat on a ‘Puck’ and load it in just a couple of minutes (there is no need to warm up the cryostat). After the low-temperature test is completed, samples can be removed easily, and within a few minutes the next sample, prepared on a spare Puck, can be loaded. The entire process from installation and cooling to the base temperature takes less than three hours, therefore enabling high-throughput screening of scientific samples and rapid prototyping of quantum electronics. |

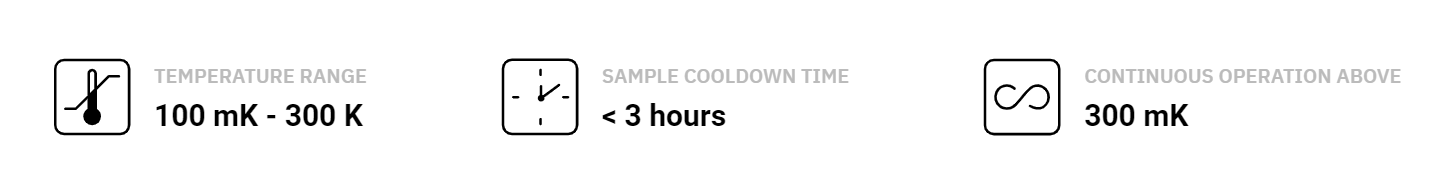

Wide temperature range ADR systems are equipped with a heat switch to decouple the solid-state cooling medium from its pre-cooling stage during the demagnetization refrigeration process. In the L-Type Rapid, the latter supports continuous operation at 300 mK and one-shot cooling down to 100 mK. The weak thermal link provided by the heat switch also enables heater-assisted continuous temperature sweeps from base to room temperature. In contrast to typical He-based refrigerators, the L-Type Rapid offers simple access to a large temperature range, making additional equipment or accessories for working with very low temperatures obsolete. |

Highly modular cooling platform Take advantage of the versatility of a modular product by configuring the device for your specific use case. Options include the integration of high-quality electronics in a variety of configurations, magnetic shielding, a 5 T sample magnet, Quantum Machines’ cryogenic control systems, and a large Puck 55. |

Options and Components

| Wiring and cryo-electronics standard DC lines can be extended with several radio frequency lines equipped with multiple RF electronic components such as amplifiers, isolators, and low-pass filters used for the characterization of quantum devices | Sample Puck 55 more space, lines and flexibility for your investigations of quantum devices and material samples |

Magnetic shielding to investigate and operate sensitive superconducting samples and quantum devices | |

5 Tesla sample magnet smooth bipolar operation to study magnetic properties |

|

| Enhanced compatibility compatible with Quantum Machines’ cryogenic control systems offering optimized interfaces and connectivity for sensitive quantum devices |

Performance Data

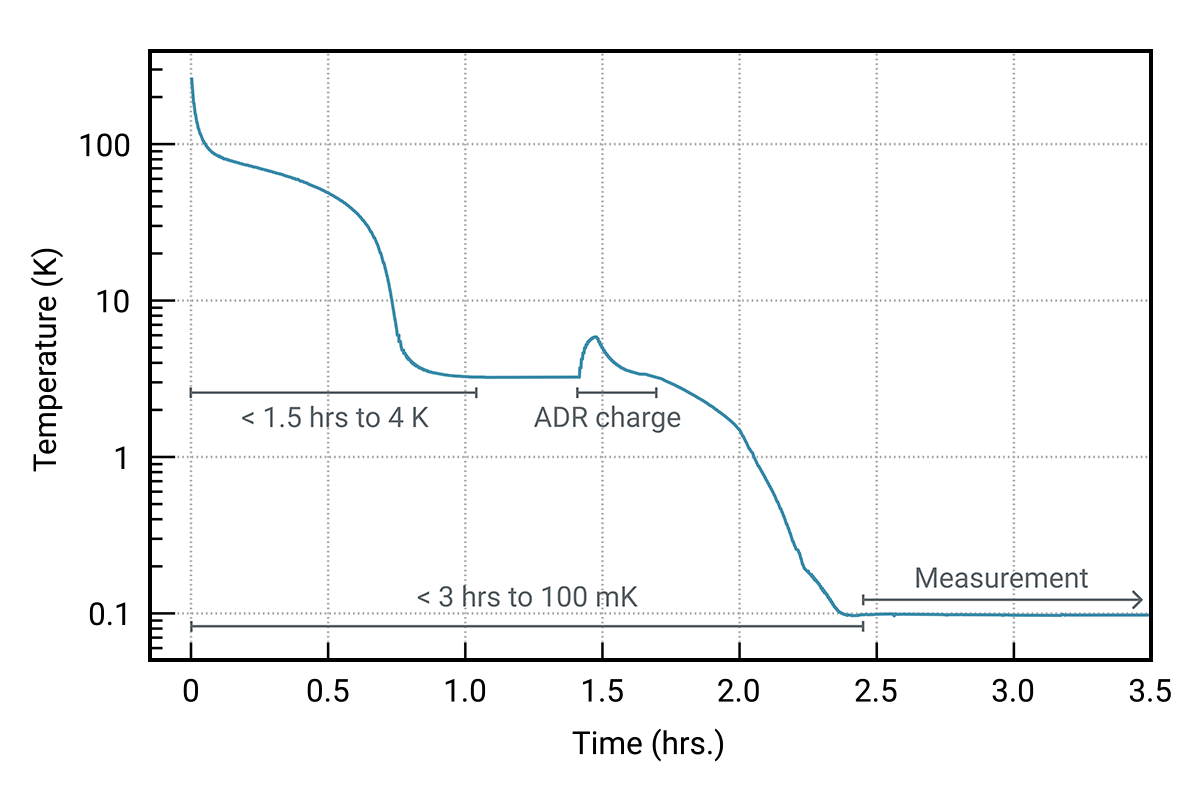

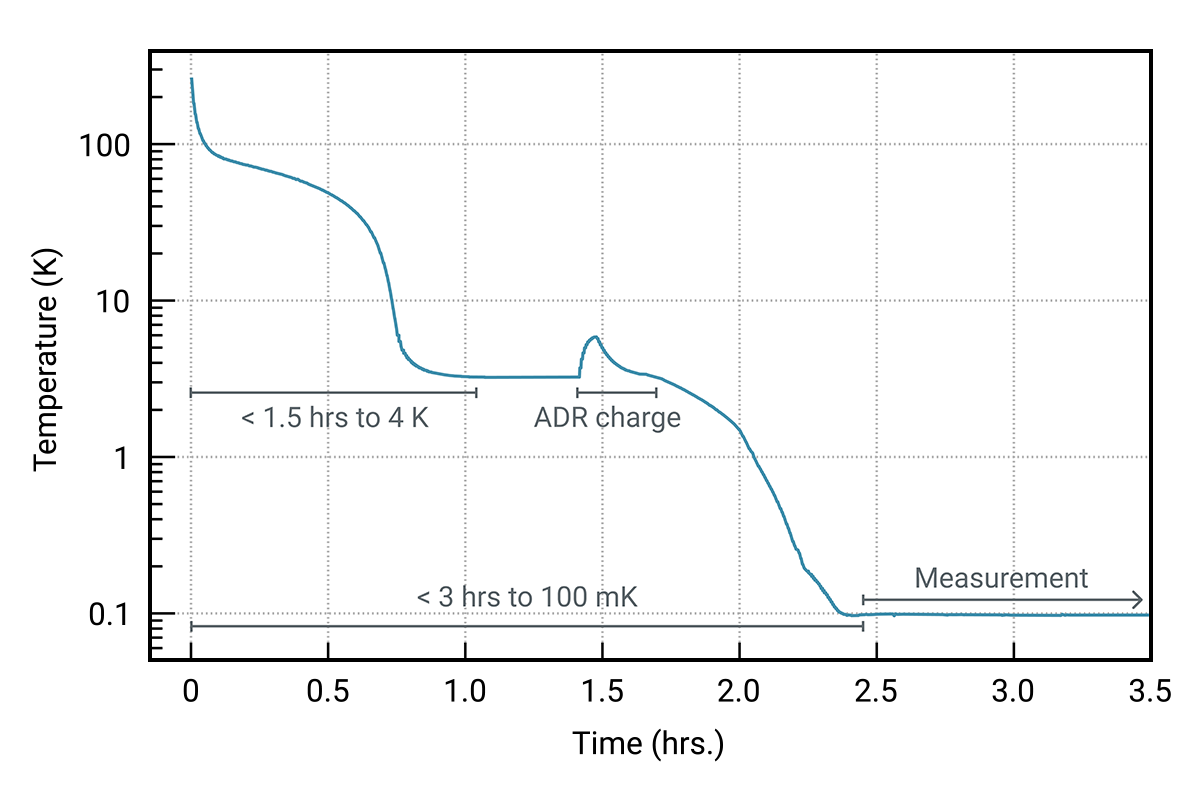

Fast and hassle-free operation

| Fast sample cooldown The cumbersome and time-consuming operation of large and complex refrigerators is a bottleneck in the development of novel functional materials as well as next-generation quantum devices. The L-Type Rapid, with its puck-based sample loader, offers a fast and automatic sample cooldown, increasing sample throughput and accelerating the screening of material samples and quantum devices. The figure shows a typical time-temperature curve for our sample puck with a test device mounted, while cooling from room temperature to sub-Kelvin temperatures. In the initial 1.5 hours, the puck is cooled to the cryocooler base temperature. After the puck is fully thermalized, the ADR cooling units can be charged. This process takes approximately 1 hour. Subsequently the demagnetization cooling is started, and the system can be operated either continuously at temperatures as low as 300 mK, or at 100 mK for a limited hold time. Apart from mounting the puck in the vacuum lock, the operation is automatic and can be controlled through a modern and intuitive instrument control software. |

|

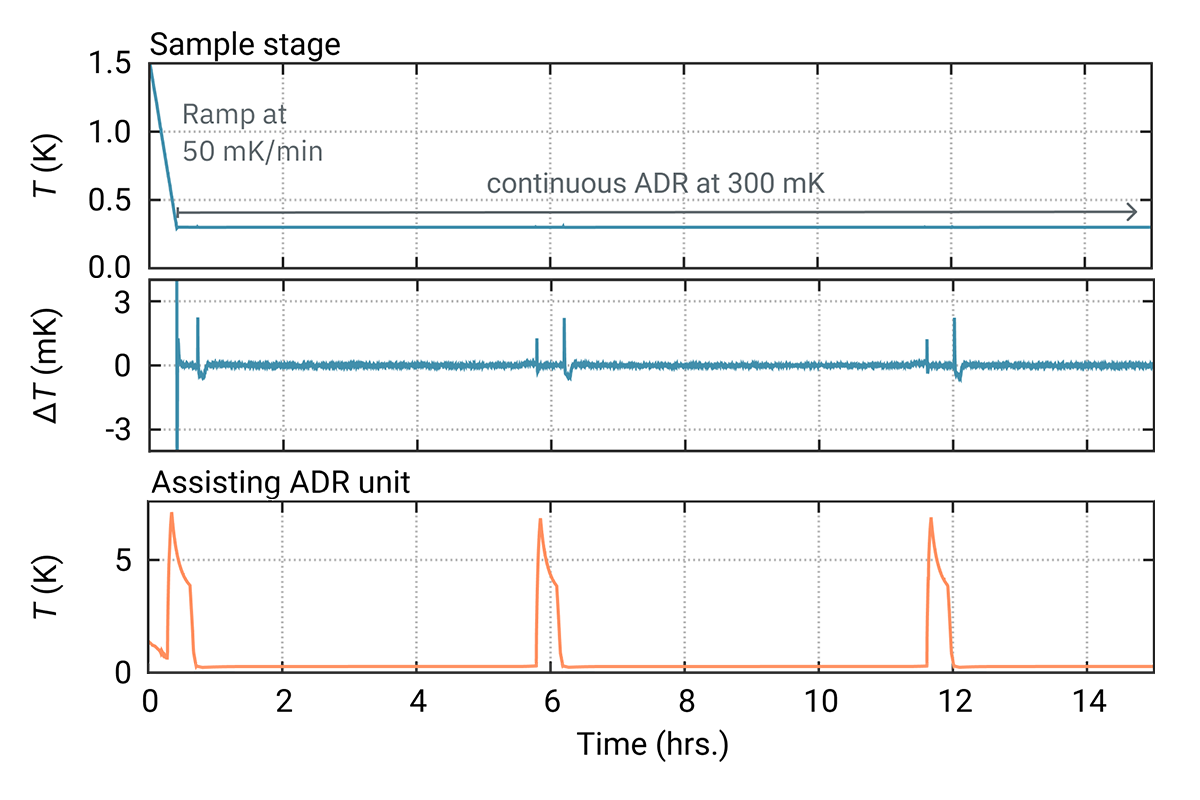

| Continuous operation at 300 mK Conventional adiabatic demagnetization refrigerators (ADR) allow only for “one-shot” cooling. By combining multiple ADR units, kiutra’s cryostats can provide both “one-shot” and additionally continuous sub-Kelvin cooling (cADR) independent of the supply with cryogens. In its standard configuration, the L-Type Rapid uses two ADR units to generate continuous cooling. The figure shows the temperatures of both ADR units running in cADR mode at 300 mK. While the first unit cycles between the 4 K main heat bath (provided by the cryocooler) and a temperature below the target temperature, the second unit controls the sample temperature. As a result, the sample stage can maintain a constant temperature of 300 mK with a typical temperature stability <0.1 %, and a slightly reduced stability <2 % when activating its heat switch to initialize the regeneration. More about Magnetic cooling |

|

Scope of supply

| Cryostat Sumitomo RP-082B2 closed-cyle pulsetube cryocooler, 1W 4.2K, 40 W @ 45 K Sumitomo F70H water-cooled indoor helium compressor, 20 m flexlines Two ADR units for one-shot and continuous operation: -2 ADR magnets -2 heat switches -2 cooling media Wide range pressure gauge Integrated passive quench protection User ports for custom integration: -2 x ISO-F 100 -1 x ISO-KF 25 |

|

| Instrument control -Custom 19” electronics rack -kiutra Modular Control Unit (MCU): Base module Power module Drive module 2x load module Gas Handling module -kiutra Compressor Control Unit (CCU) -Temperature monitor -Temperature controller -Calibrated temperature sensor on sample stage -Temperature sensors on cryocooler cold stages and first ADR unit -Sample heater and warm-up heater -User PC with pre-configuration Python-based instrument control software and high-definition display -2x digital high frequency magnet power supply -User breakout -Filtered temperature sensor breakout | Standard wiring -40 DC wires |

| Gas handling -Pumping, purging and venting of cryostat and Sample Changer airlock chamber -Oil-free roughing pump -Turbomolecular pump | Sample changer -Airlock chamber with motorized sample transfer -Sample Puck Transfer Cage -Additional pressure gauge. -1 Sample Puck -1 Sample Puck Testing Station -1 Sample Puck Testing Station |